Innovative tension technology for slitting lines:

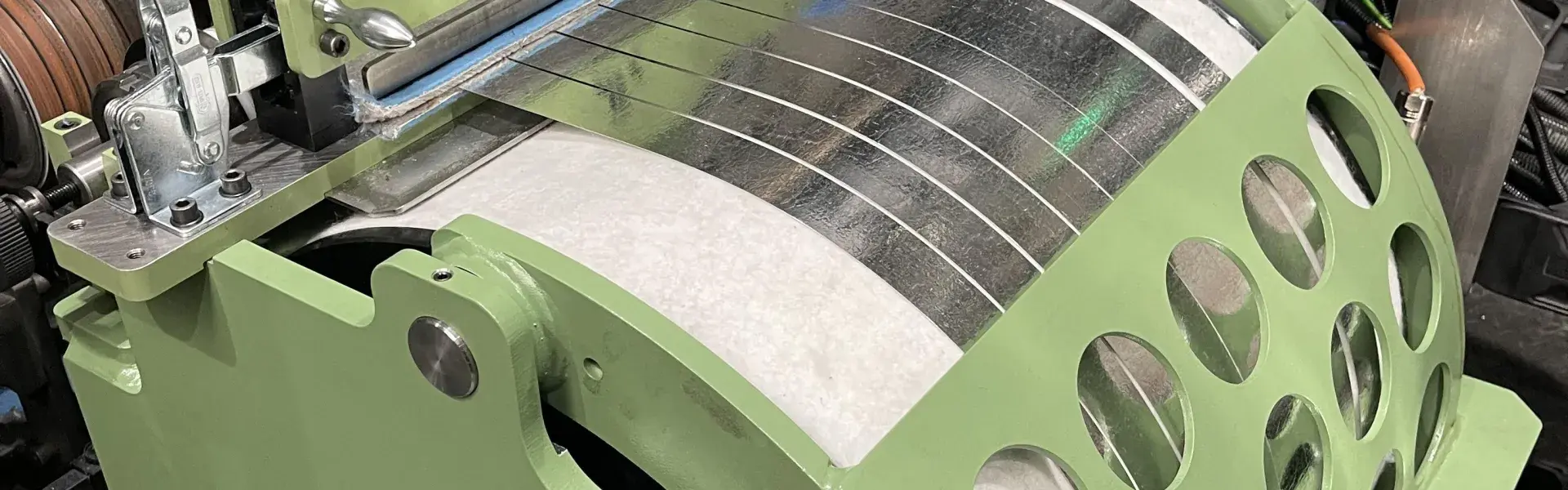

The new vacuum tension roll system from NOBAG

At a long-standing NOBAG customer, we were able to expand the existing system with an innovative variant of a vacuum brake roller.

With this new, innovative system, customers can continue to use the proven methods of felt or belt tension systems, but now complemented by the newly introduced vacuum tension roll. This has been specially developed for thin and narrow strips and offers a variety of advantages.

This vacuum tension roll is characterized by optimisation of its energy efficiency and enables precise control of the braking force. This is supported by a retrofittable tension measurement, which enables even more precise control of the tension system. The innovative vacuum tension roll system from NOBAG offers reliable and precise braking technology, especially for slitting lines.

The use of this system optimizes production processes and ensures the production of high-quality strips. The vacuum tension roll system proves to be extremely effective and reliable, especially when processing sensitive coil surfaces. It enables gentle handling of materials and thus makes a significant contribution to increasing product quality.

Overall, with the new vacuum roller braking system, NOBAG is once again demonstrating its innovative strength and commitment to first-class solutions in tension technology. Customers can count on a reliable, energy-optimise and precise tension solution that optimizes their production processes and helps them to manufacture high-quality end products.