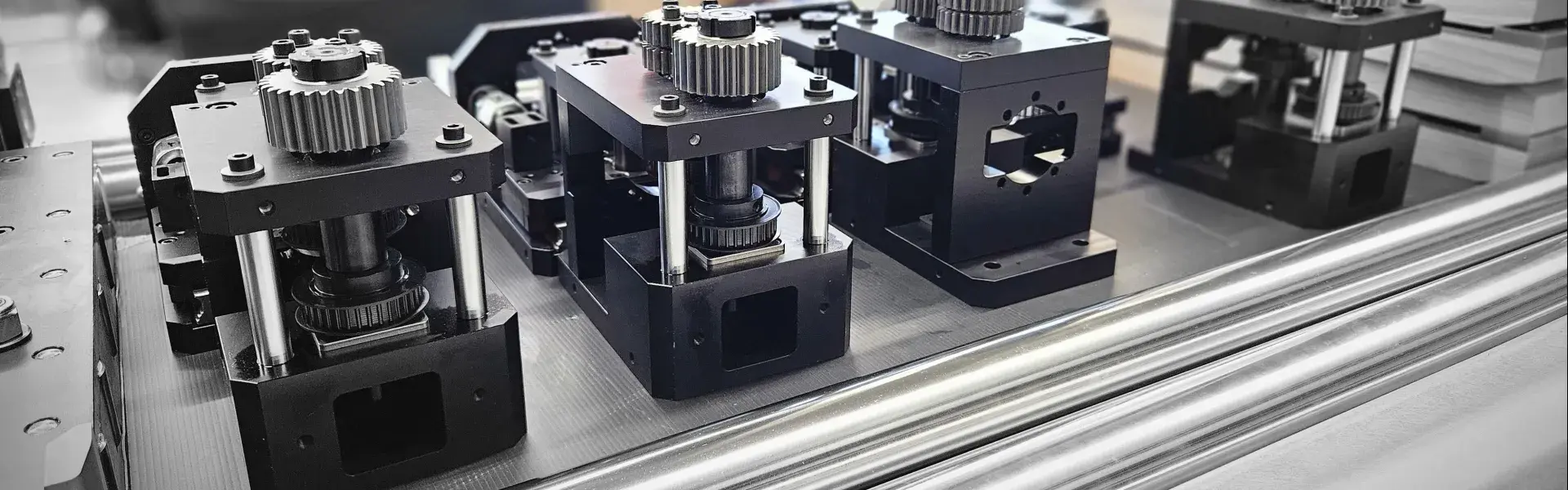

Customized machines and systems according to customer requirements:

Areas of experience

Plant engineering

- Machines for edge rounding

- Rod handling (for 8m rods)

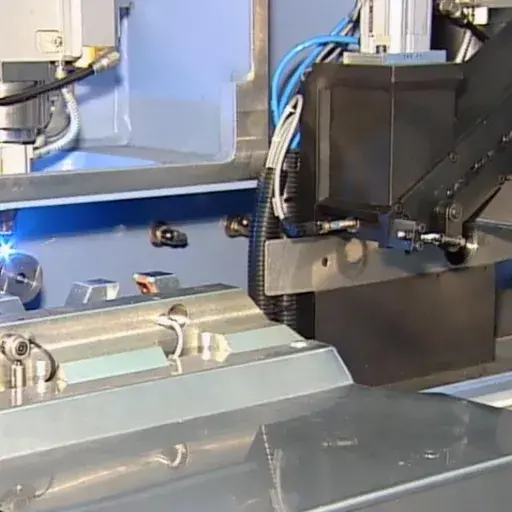

- Laser welding systems for specific parts

- Laser cutting systems for specific parts

- 3D printers for metal geometries, with laser melting process

- Lapping machines for optical glass

- Mech. laboratory press (27t) for test workshop

- Equipment in ATEX zone

- Handling systems in clean room

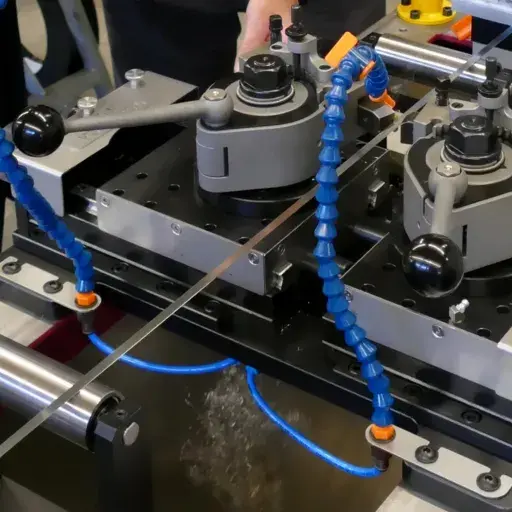

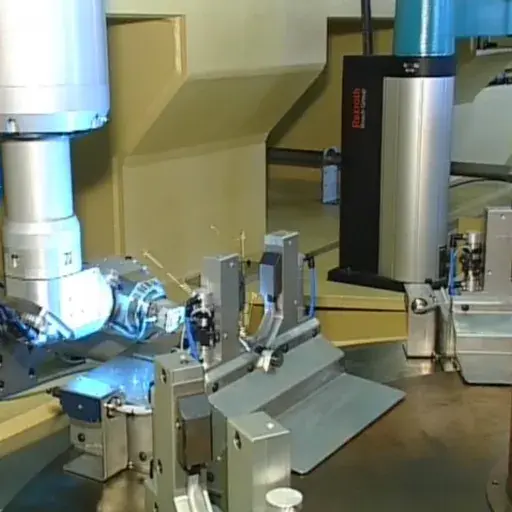

Fixture construction

- Clamping systems for laser welding

- Measuring and testing equipment

Automatic machines

- Rotary transfer machines

- Assembly machines

- Deburring stations

Downloads

Special machines EN

1.24 MB

#Project examples

Project examples

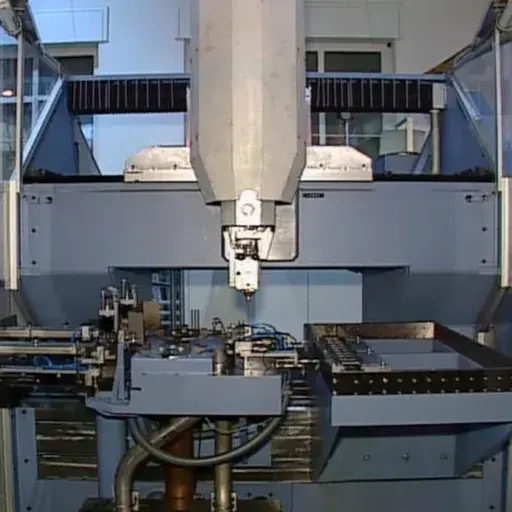

Drill rod handling

Drill rods are used in rotary drilling rigs for geological drilling. They connect the drill bit to the drive.

In order to be able to connect the drill rods during repositioning, their end is machined using several automatic threading machines.

NOBAG develops and manufactures the handling system for transport in the processing line.

Installation specification

| Length | 8.2 | m |

| Width | 14.2 | m |

| Height | 3.1 | m |

| Weight | 35 | t |

| Part size | ø28x8000 | mm |

| No. of grippers | 30 | |

| Machining cycle | 120 | bars/h |

#Special presses

Special presses

Servo presses, mechanical and hydraulic presses are designed and manufactured according to customer specifications.