With cold forming technology, a wide range of formed components can be produced cost-effectively, in large quantities, with high dimensional accuracy and good surface properties.

#Cold forming presses

Cold forming presses

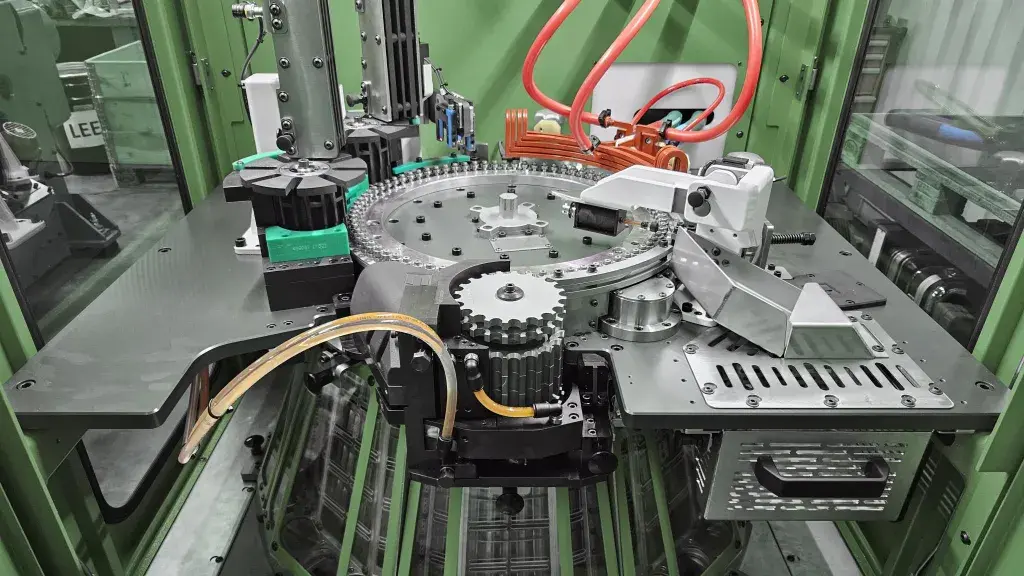

NOBAG develops and produces mechanical, hydraulic and servo-electric presses for the cold forming of hollow and solid parts made of steel, aluminum and non-ferrous metals.

We are your competent partner for cold forming technology, with a focus on the production of hollow bodies.

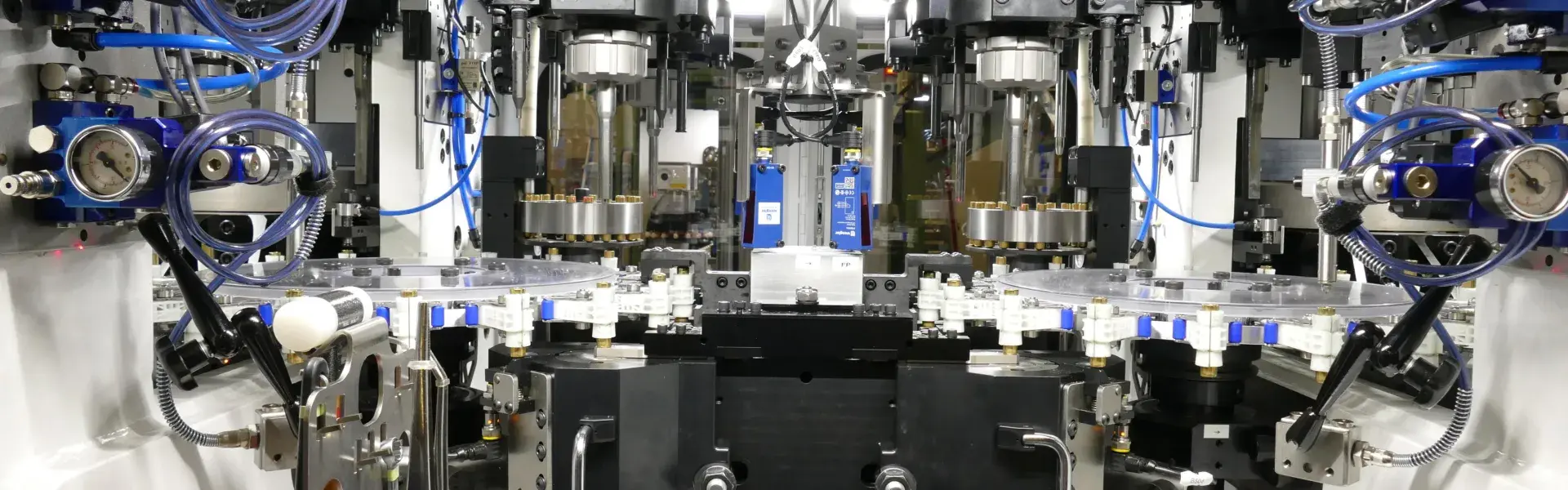

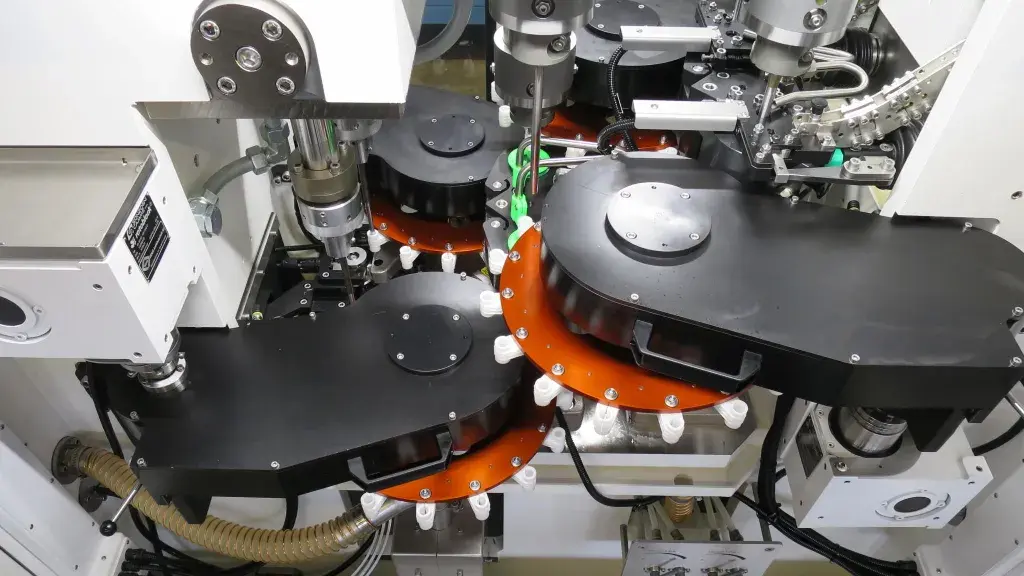

Combined presses / multi-stage presses

Combined presses to increase efficiency with a nominal output of up to 240 pcs/min

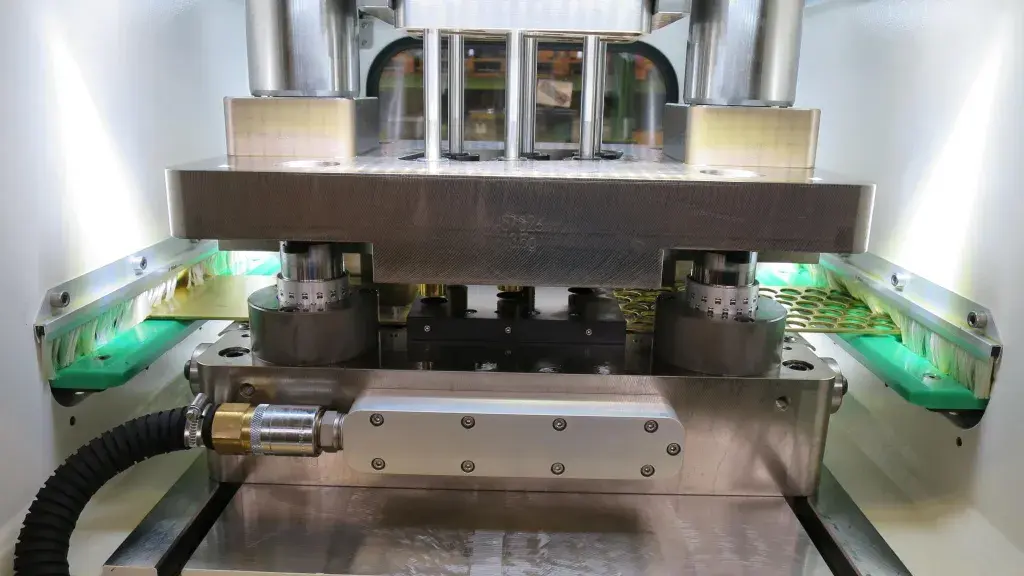

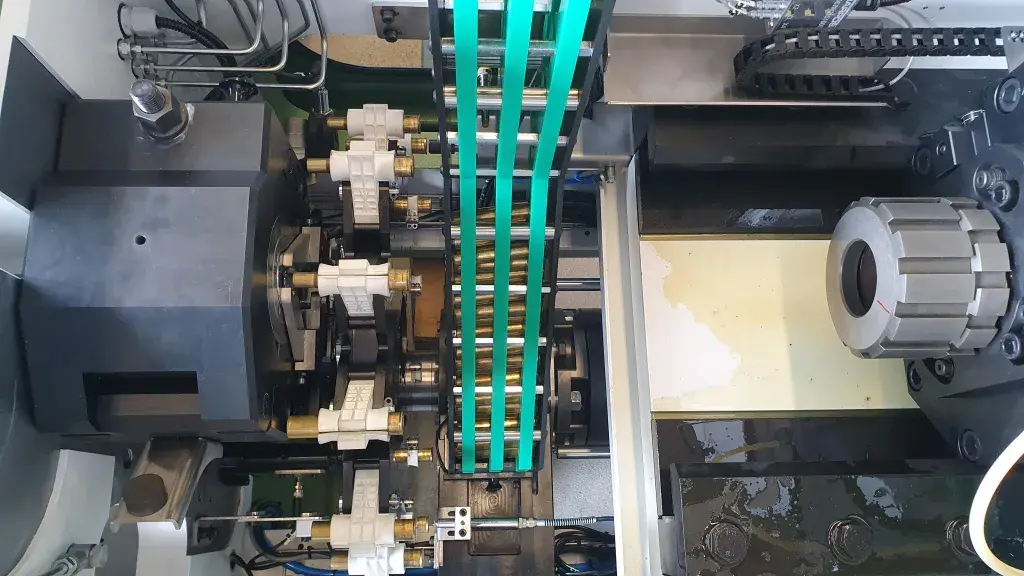

Cupping press type NP

In a double-stroke process, this press produces a roundelle from the strip in the first step and then directly produces the cup in the same stroke.

Depending on the cavity of the tool block, over 1,000 parts per minute are produced. This means that several case lines can be supplied with one cupping press.

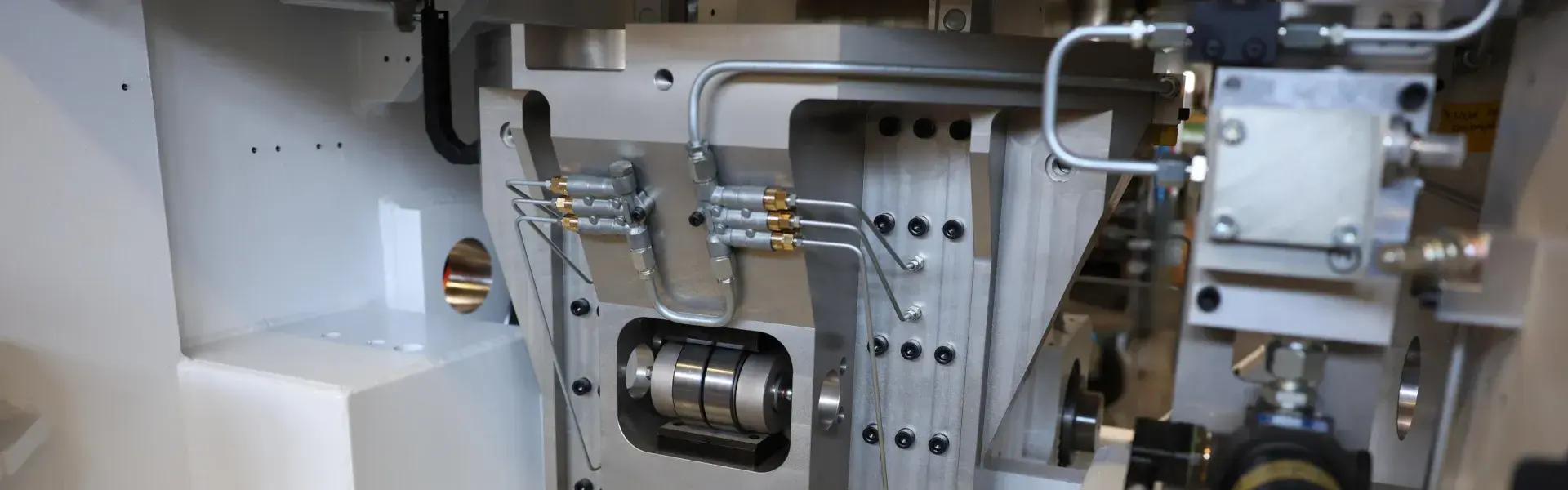

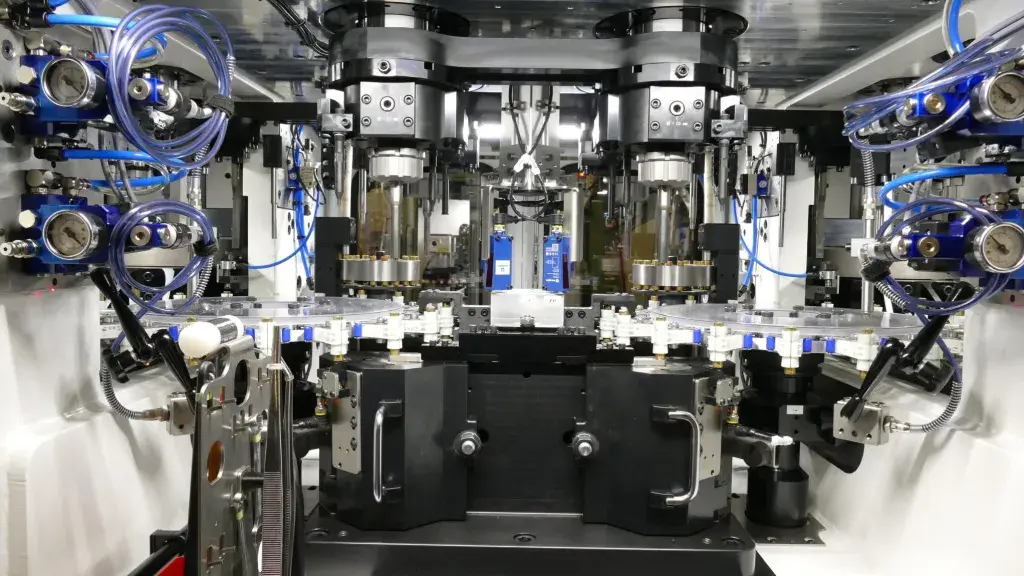

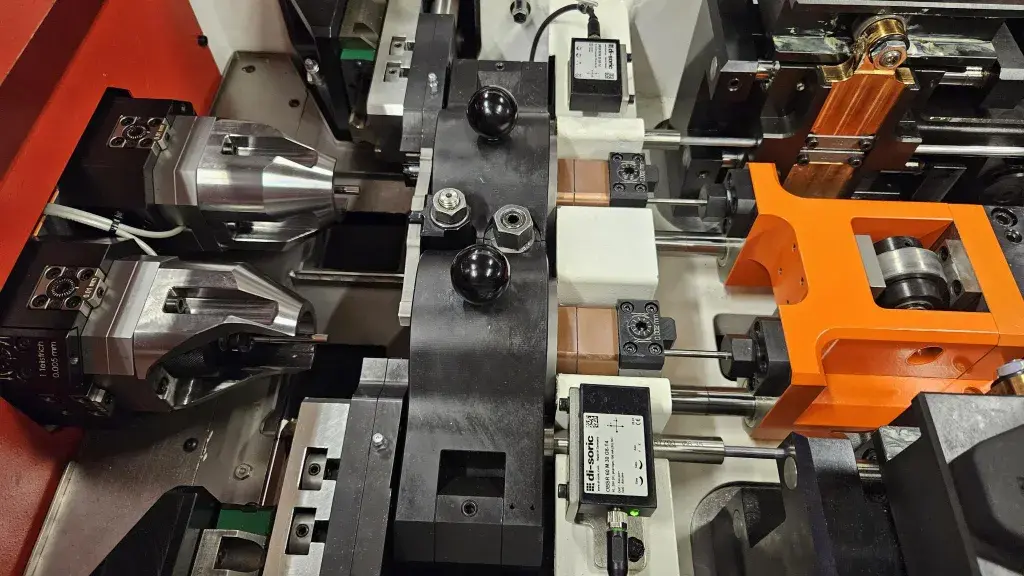

Combined draw press type KZP

This press is designed, among other things, for drawing steel or brass cases from the cup and has up to three drawing stages with a unique processing concept. The products are cut to the correct length immediately after drawing.

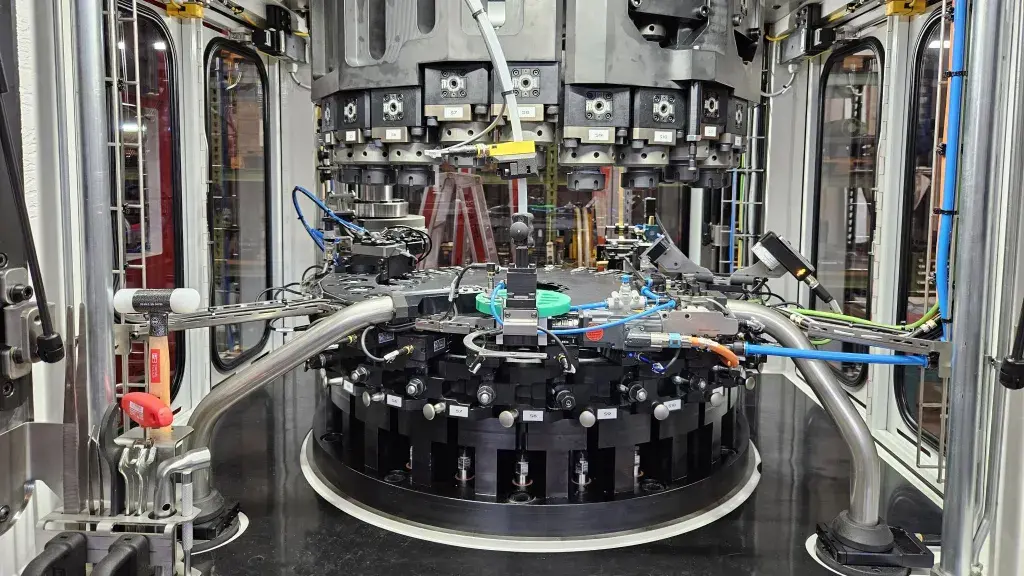

Combined heading and tapering press type KBEP

This press is designed for, among other things, heading, necking, piercing, tapering and calibrating of steel or brass cases. For forming, it is equipped with a unique double toggle lever for the best forming results.

Other forward or reverse extrusion processes can also be performed.

Single presses / single-stage presses

Single-stage presses to increase production flexibility with an output of up to 100 / 240 pcs/min.

Each machine performs one operation and, depending on the product size, can be used with two tools for double output.

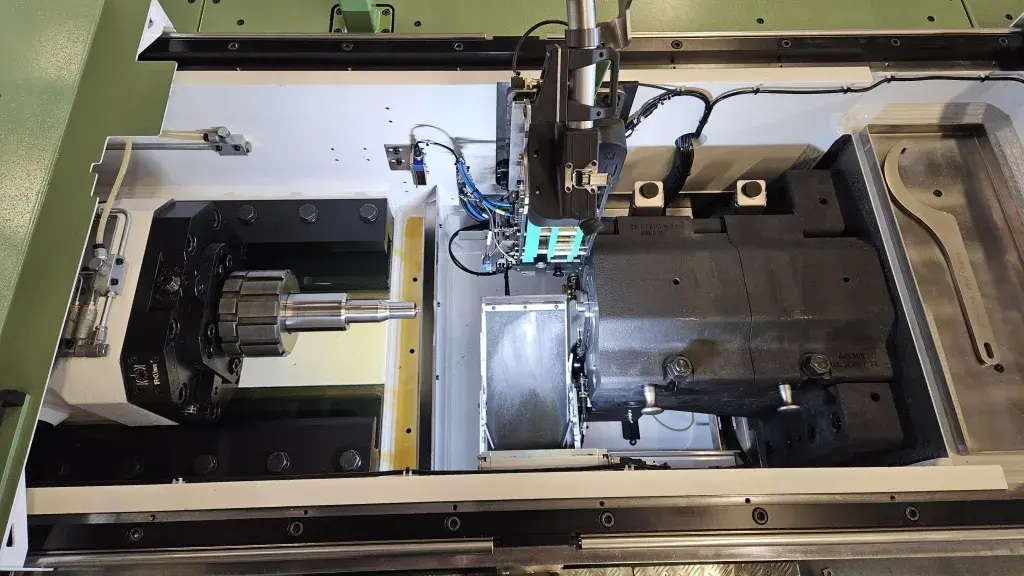

Draw press Type WON 2 / WON 5

This press is designed, among other things, for drawing steel or brass cases.

Heading press Type WON 3 / WON 6

The press is designed, among other things, for the bottom pressing of steel or brass cases.

For forming, it is equipped with a unique toggle lever for the best forming results.

Other forward or reverse extrusion operations can also be performed.

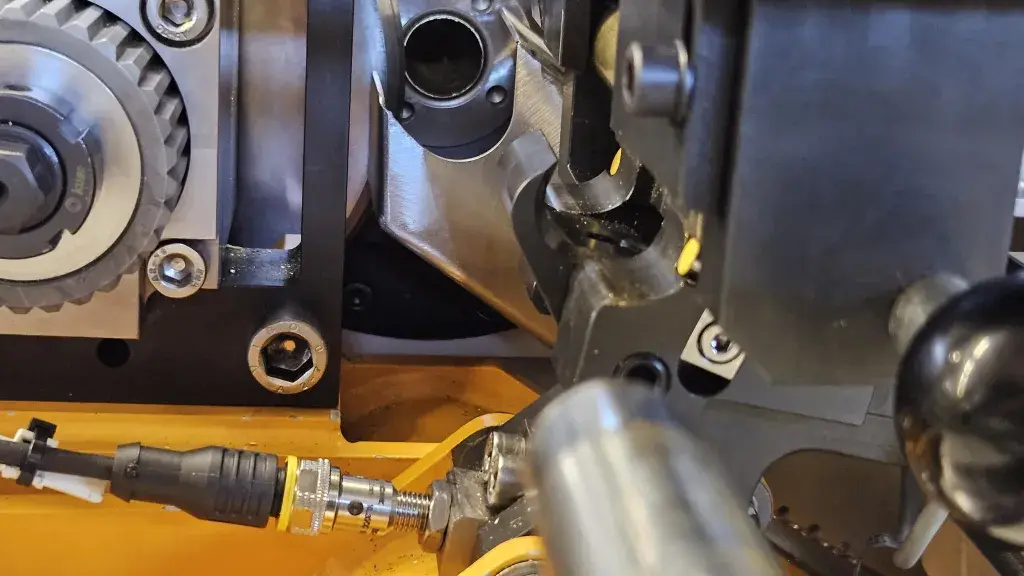

Tappering press Type WON 4 / WON 7

The press is designed, among other things, for tapering and calibrating steel or brass cases.

Depending on the product size, it also has the option of piercing a fire hole directly in the machine.

#Additional machines

Additional machines

Machines for special tasks

NOBAG develops and produces machines in partnership with our customers. In this combination, we contribute to your market success.

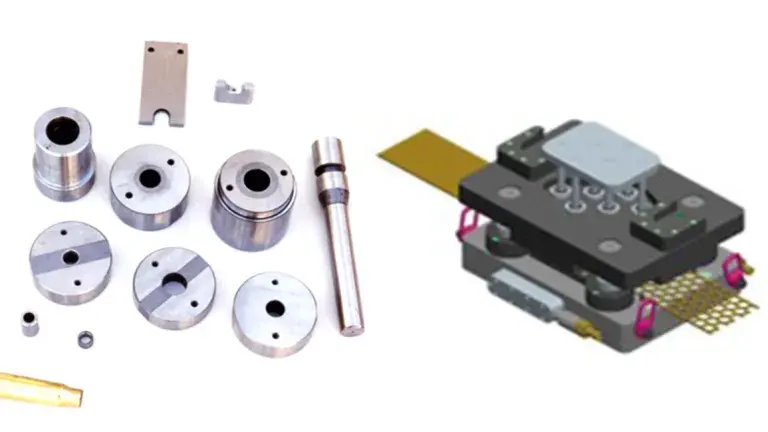

Core press Type KP

Core presses are suitable for forming bullet cores from wire made of lead and other materials. They deliver outstanding product accuracy for maximum bullet precision.

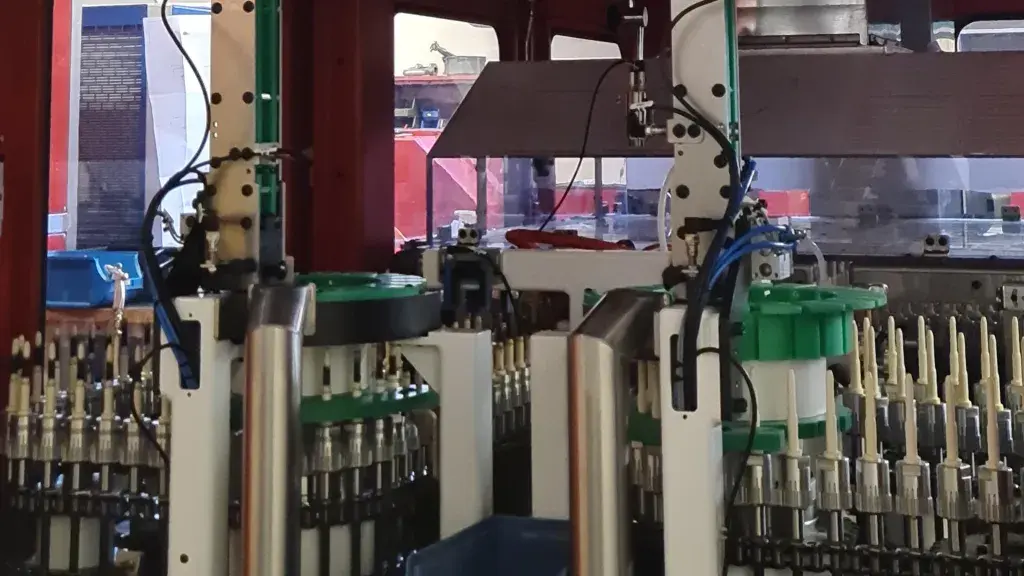

Bullet press Type KGSP

Bullet presses form the bullet jacket, insert the bullet core into the jacket, close off the tail and finish the bullets with a groove and/or other geometry definitions.

Machines for intermediate processes

Trimming machine Type BSA

The trimming machine is primarily used to cut deep-drawn parts to the correct length.

Recrystallization annealing machine Type RGM

The recrystallization annealing machine is used to anneal cold-formed hollow bodies in order to equalize the material stresses and reduce the hardness.

Neck annealing machine Type HGM

The neck annealing machine only anneals the mouth of the cold-formed hollow bodies, thereby improving the material properties again.

#Toolmaking

Tool Engineering

From engineering to the commissioning of drawing and cold forming tools, everything from a single source.

Downloads

KFP Flyer EN

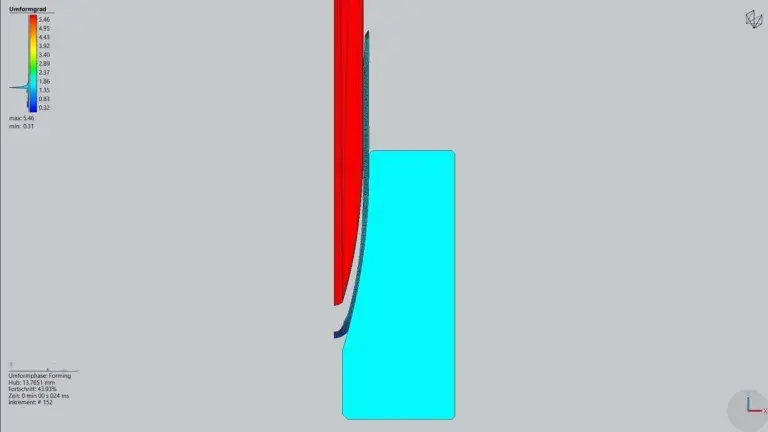

#Process development

Process development

We offer more than just machines

In addition to our machine portfolio, we support our customers in forming technology and thus in the process engineering of individual operations or overall production. In doing so, we define the starting material, gradation of processing through the individual forming steps, intermediate stages, process-relevant chemical and thermal treatments, tools and starting products.

- Product definition

- Process engineering

- Process parameters

- Forming stages

- Tool geometry

- Intermediate treatment

- Structural analysis

- Evaluation of test results

- Commissioning and process optimization

- Production support

- Troubleshooting and improvement solutions