We offer you state-of-the-art solutions for the efficient and precise processing of strips. Our specialized slitters, slitting lines and coil processing lines are designed to optimize your production processes and ensure the highest quality.

We are happy to present our customized solutions to you in detail on the following pages:

#slitting_lines

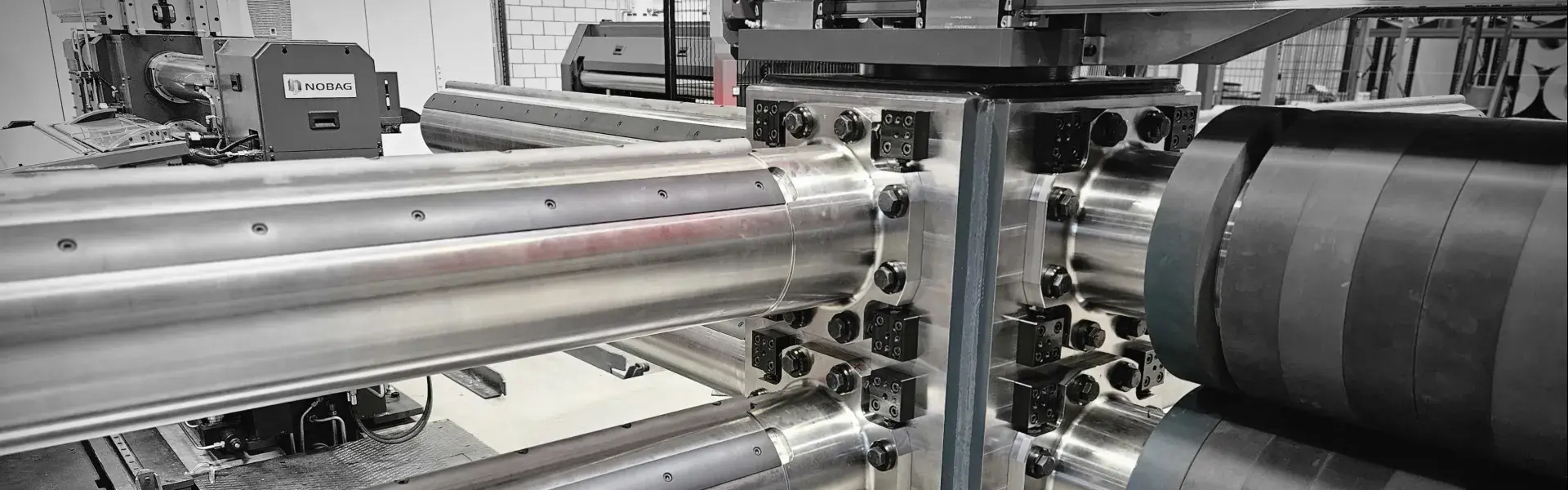

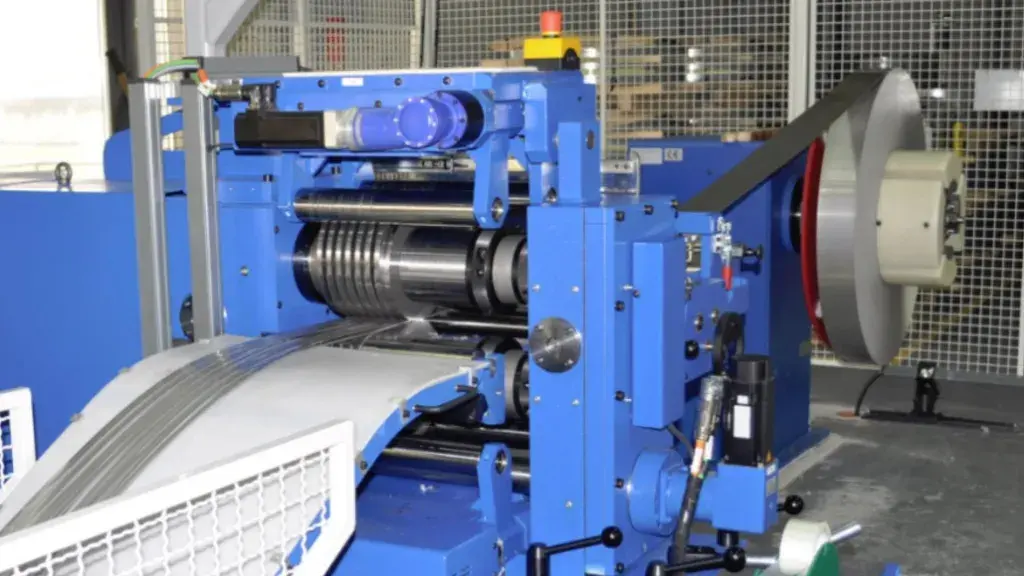

Slitting lines

Slitting

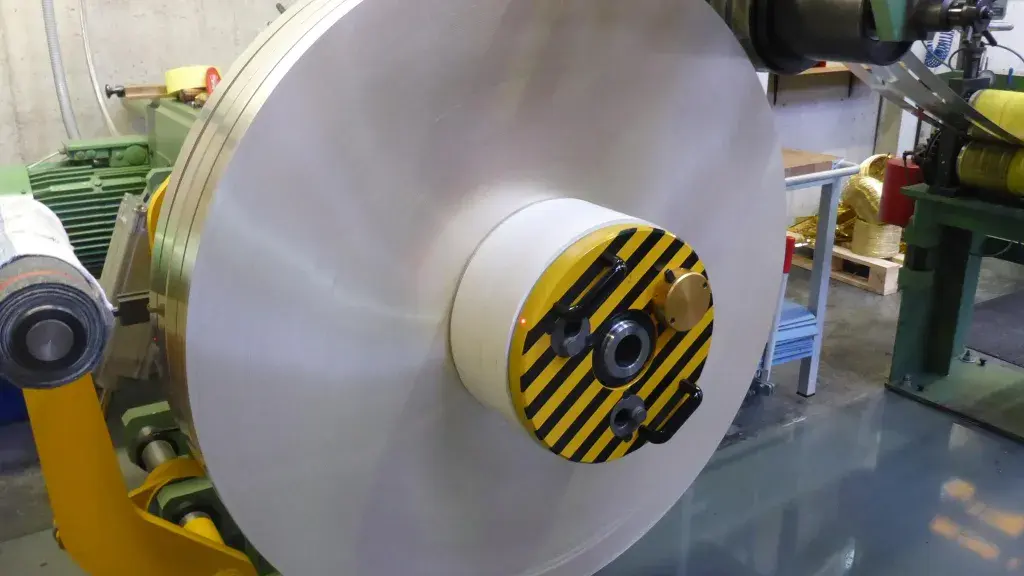

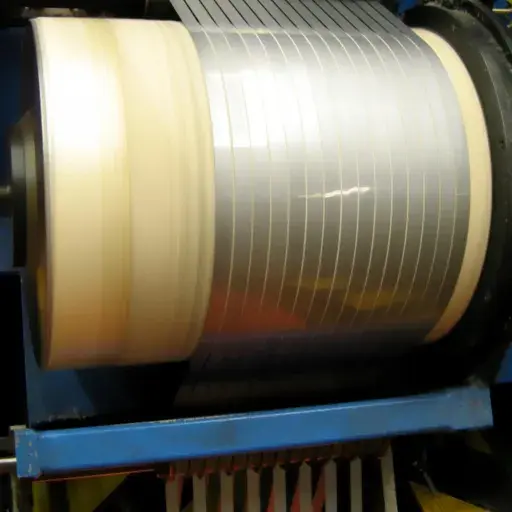

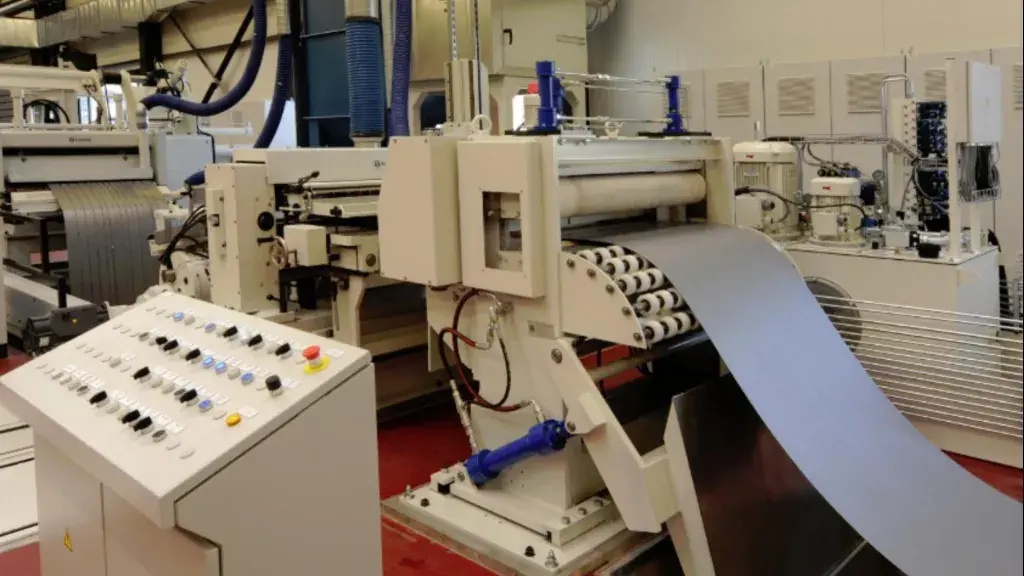

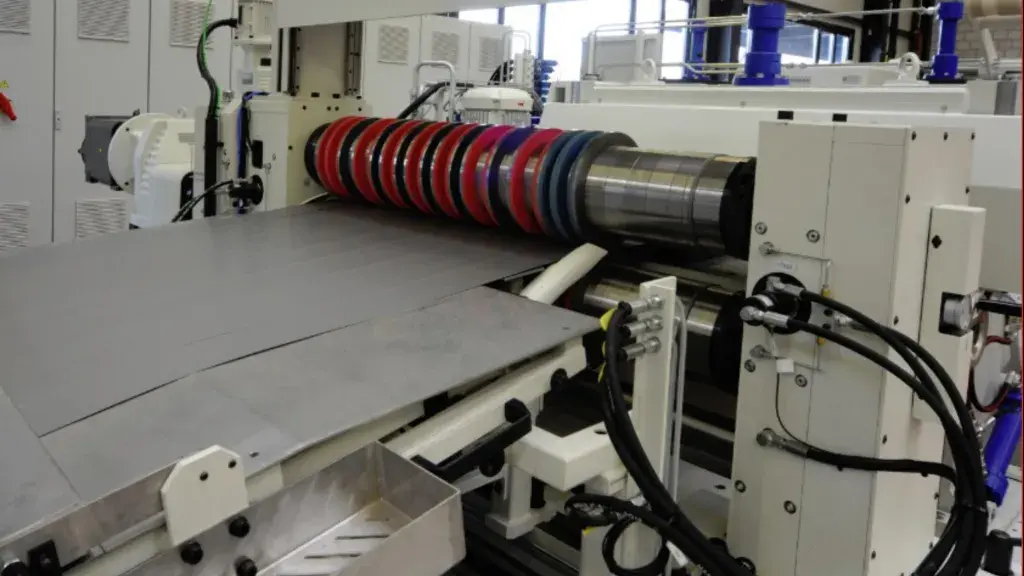

Coils produced in rolling mills are slit on slitting lines to narrow strands. They are the pre-product for punching and bending of final goods like razor blades, hose clips, flat cables and connectors for electronic wires, automotive stampings, rotor and stator lamination of electro motors, and many other goods.

NOBAG slitting lines fulfill the highest requirement regarding edge quality, precision, and productivity. Each slitting line is customized to the individual needs of the customer.

Range of application

| Materials | All types of metals, coated metals, sandwich construction materials, carbon materials (prepregs), special materials |

| Coil weight | up to 15 t |

| Coil width | up to 1450 mm |

| Strip width | 0.5 - 1450 mm |

Strip thickness | 0.01 - 4.00 mm |

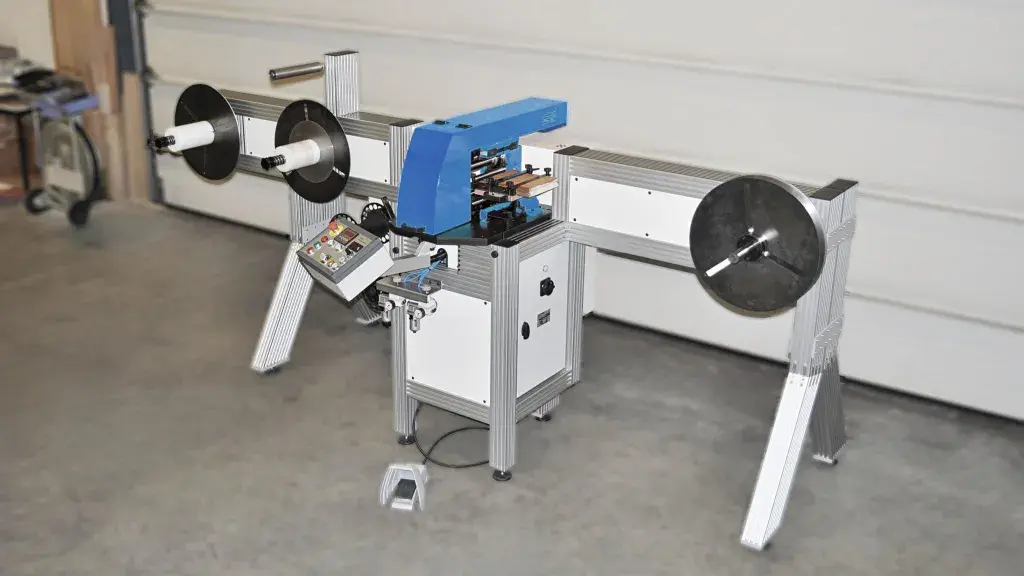

Standard Slitting Lines

Standard slitting lines are striking for their functionality and design and offer the best price-performance ratio.

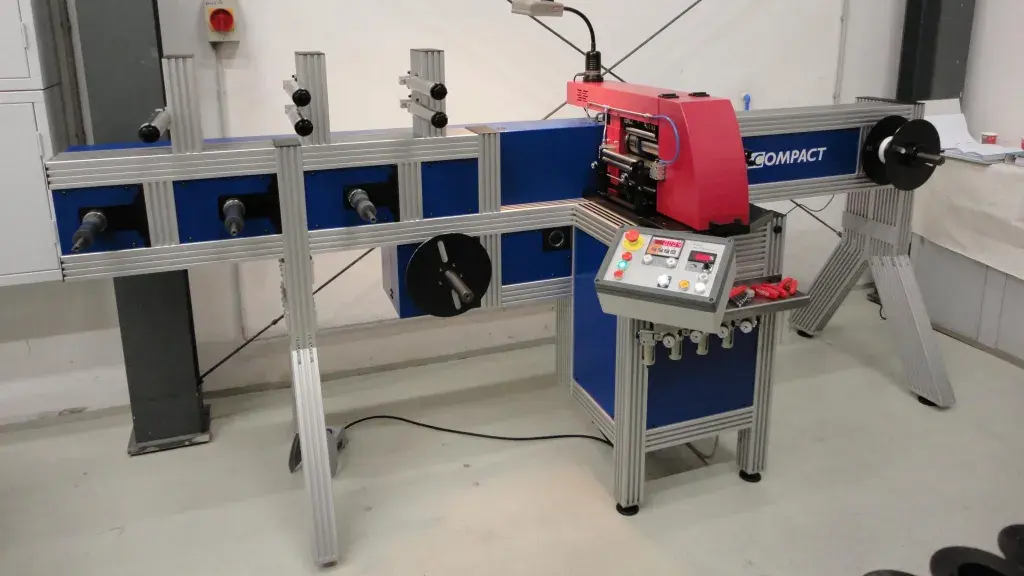

COMPACT

| Strip thickness | 0.01 - 0.8 | mm |

| Strip width | 0.5 - 100 200 | mm |

| Coil weight | 250 | kg |

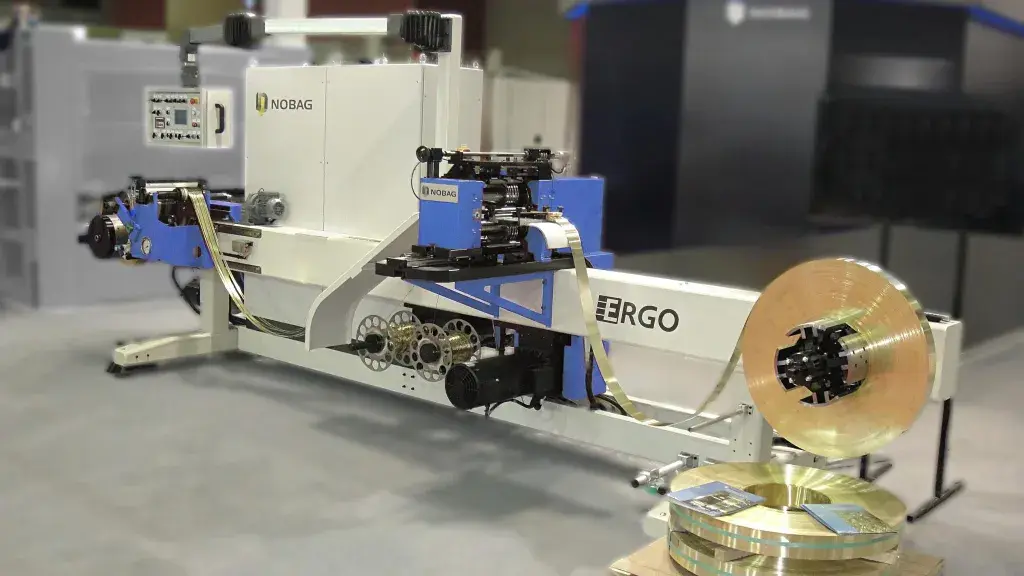

ERGO

| Strip thickness | 0.03 - 1.0 | mm |

| Strip width | 0.5 - 200 300 | mm |

| Coil weight | 1000 | kg |

SLM 30 ES

| Strip thickness | 0.05 - 1.5 | mm |

| Strip width | 4 - 300 | mm |

| Coil weight | 2000 3000 | kg |

#slitter_types

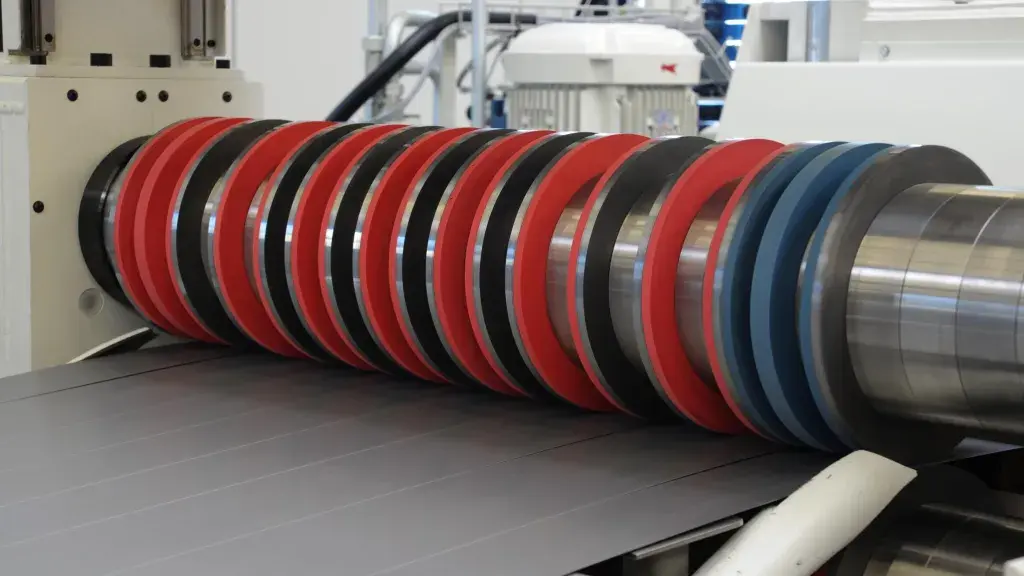

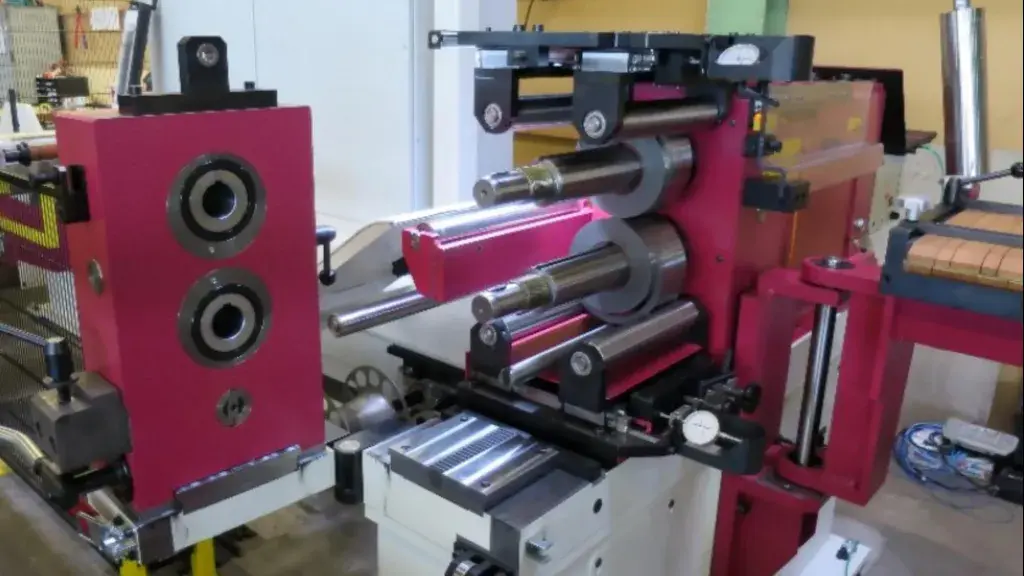

Slitter Types

Competencies

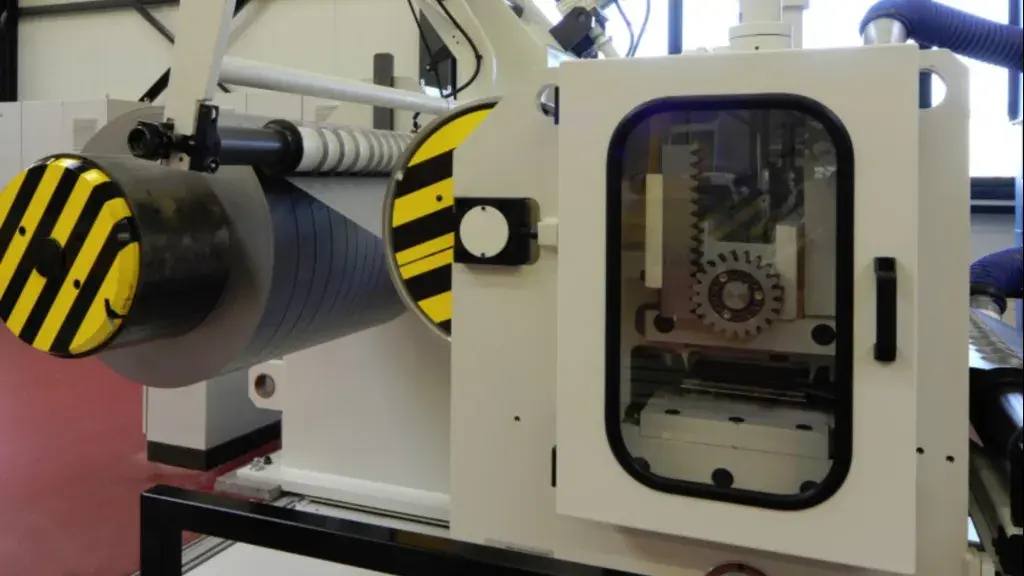

NOBS® slitter represent our worldwide reputation and they are the benchmark for the future. The first slitter was delivered in 1922. Since then, we combine engineering know how and experience with new innovative solutions, redefining technical limits with every delivery.

Slitter sizes (dimensions in mm)

| Slitter type | Nominal Knife diameter | Nominal Slitting width | Nominal Material thickness |

|---|---|---|---|

| COMPACT | 90 | 110 (200) | 0.01 - 0.8 |

| ERGO | 140 | 200 | 0.03 - 1.0 |

| SL | 160 | 320 | 0.04 - 1.0 |

| SLM | 180 | 500 | 0.05 - 1.5 |

| SM | 200 | 700 | 0.05 - 2.0 |

| SMM | 255 | 1000 | 0.07 - 3.0 |

| SMS | 320 | 1250 | 0.10 - 3.5 |

| SS | 400 | 1250 (1600) | 0.10 - 4.0 |

#coil_processing

Coil processing lines

In addition to the high-precision slitting lines, other machines and components complete the portfolio in coil processing to meet the needs of our customers in the best possible way.

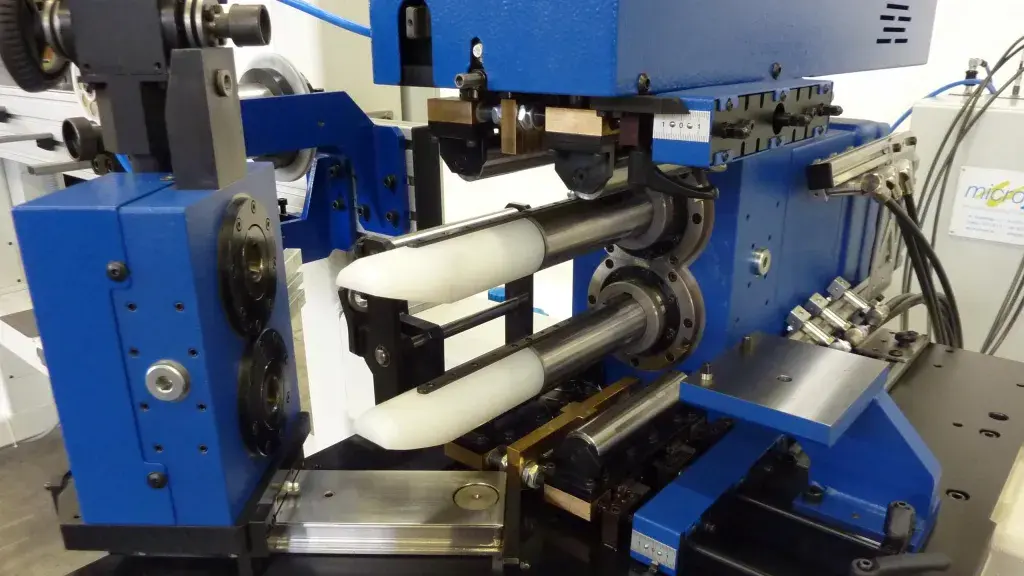

Strip edge conditioning lines

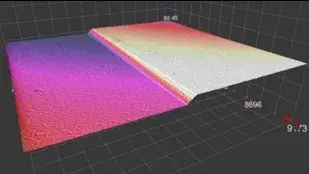

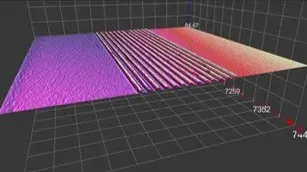

Rounding refers to the reworking of the edges of slit strips (produced on slitting lines). The edges can be rounded, chamfered or according to other customer geometry requirements. The processing can be carried out by cutting (dry or wet) or without cutting.

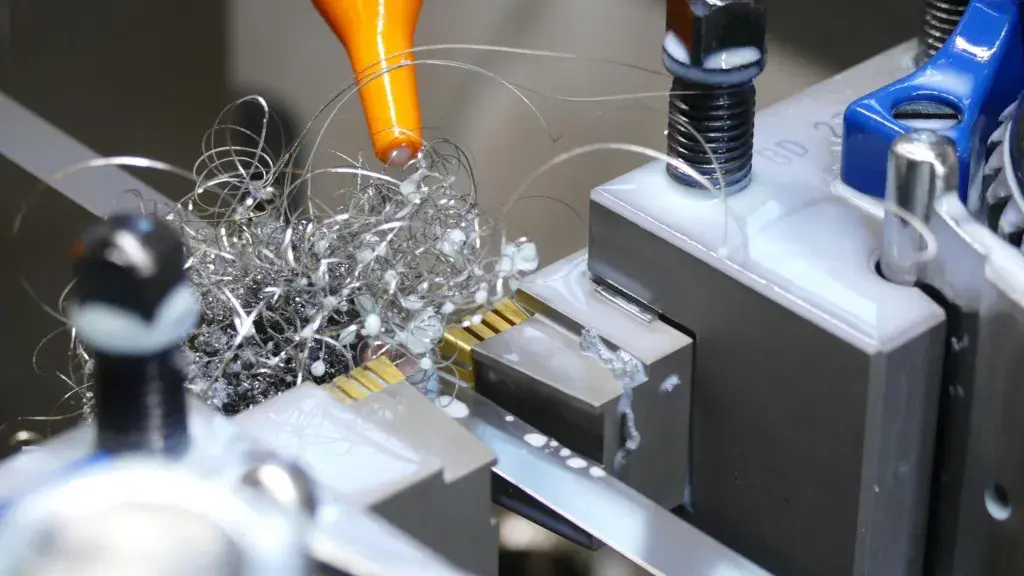

Skiving lines

Skiving machines can be used to skive a geometry into a slit strip. The machine concept is similar to that of an edge processing machine. Skived strips are often used in the electrical industry.

Edge trimming lines / trimming shears

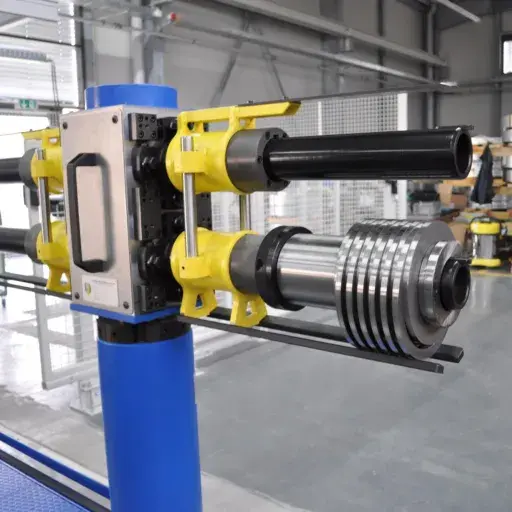

NOBAG trimming shears are used in particular for their precision and robustness. Separately driven cutter heads, absolute measurement of all movements and settings as well as an automatically adjustable gap are just some of the many special features.

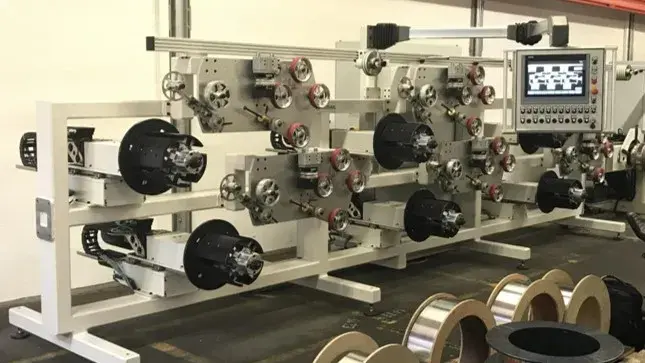

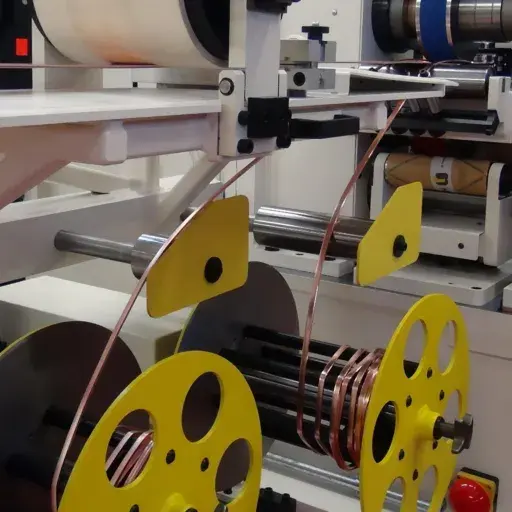

Spooling lines / Traverse winders

Strips are wound onto spools (oscillating with many layers) so that the longest possible wire length per unit (spool) can be processed with narrow strips. This increases the line running time on downstream machines (e.g. automatic punching presses). Traverse winders can be used in slitting lines, edge processing lines, annealing lines and other coil processing lines

Slip-Tech friction winding systems

The major advantage of Slip-Tech recoiling systems is that a loop pit is no longer necessary. This leads to a significant reduction in construction costs and also increases the flexibility of the machine location. In many applications, it is also possible to dispense with a tension stand, which prevents damage to delicate material surfaces.

Rewinding systems

Packaging systems / binding lines

We design packaging systems for slit strips according to the needs of our customers, from simple tilting and stacking units to complex systems with automatic strapping, weighing, labeling and automatic stacking to the desired storage location.

#Components

Components

Downloads

Coil processing_en

#Project examples

Project examples

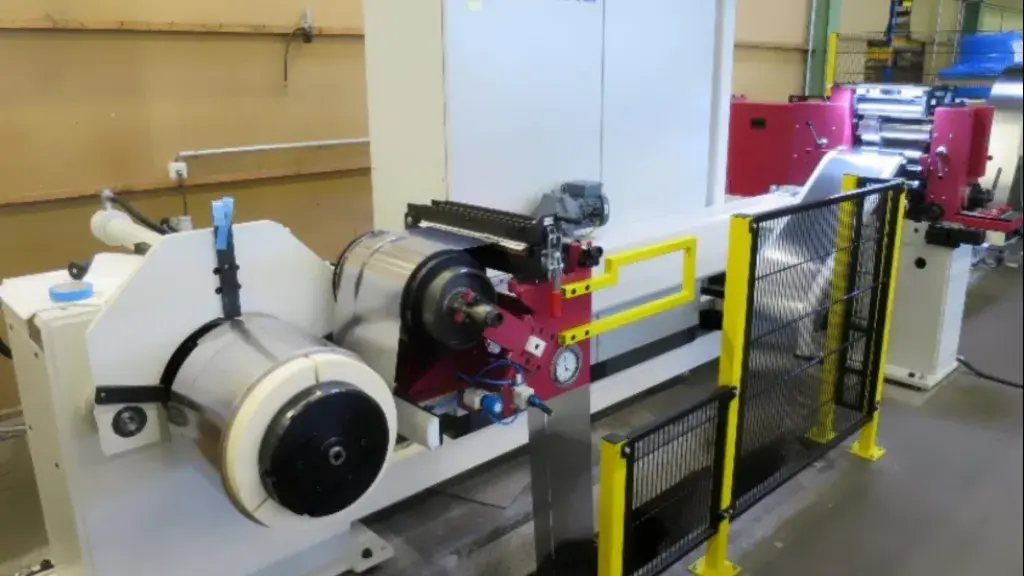

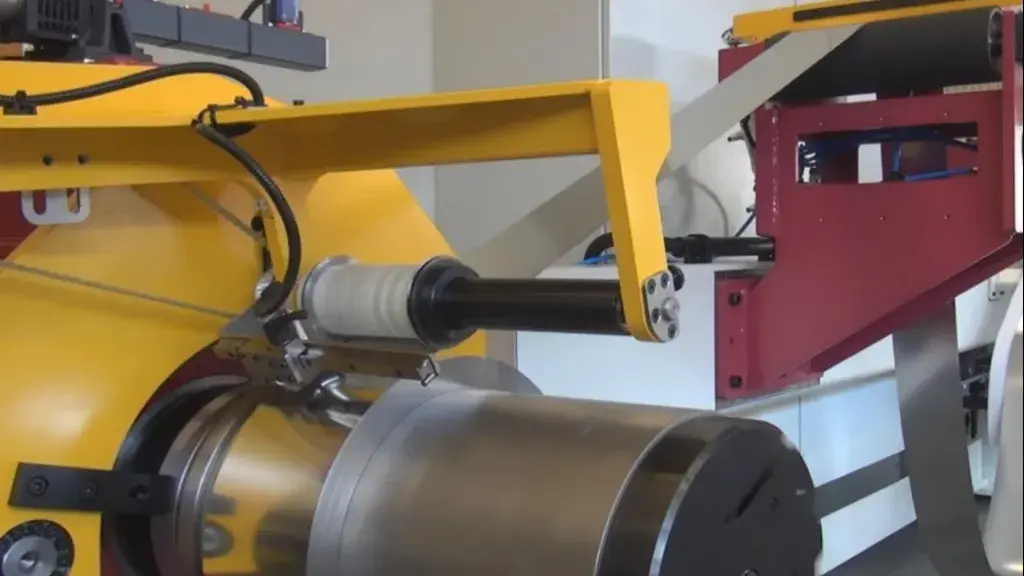

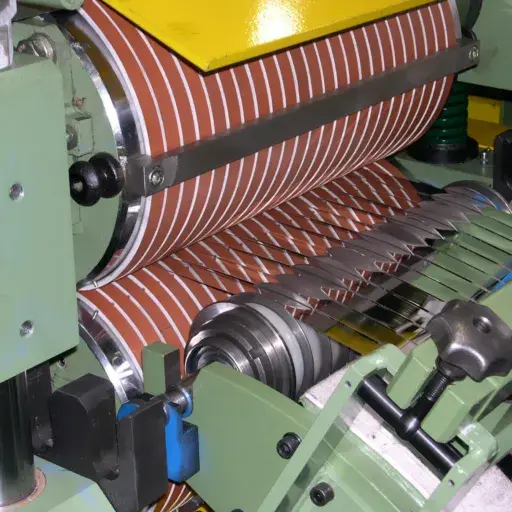

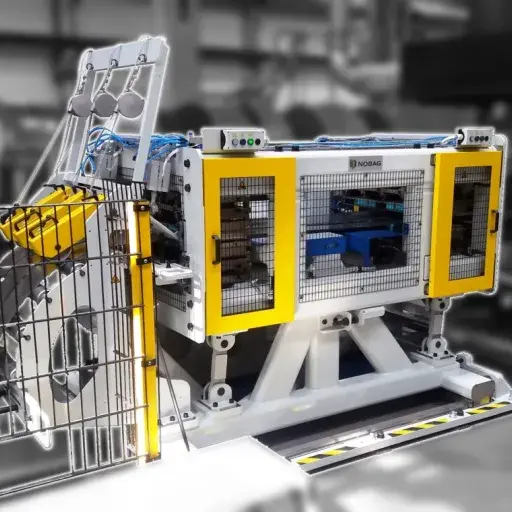

Slitting line SMM 125

The SMM 125 slitting line for transformer sheets is equipped with a high level of operating convenience. Components such as coil turners have been integrated to enable safe positioning and loading of the coils, regardless of the type of delivery.

Automatic infeed of the belt guarantees short downtimes. The ROTO waste strip cutter used fulfils all expectations in terms of performance and noise.

Line specification

| Inlet width | max | 1250 | mm |

| Material thickness | min/max | 0.2 – 0.65 (1.0) | mm |

| Bundle weight | 13 | t | |

| Bund- outside Ø | max | 1400 | mm |

| Cutting speed | min/max | 15 – 400 | m/min |

| Blade shaft diameter | 165 | mm | |

| Blade outer diameter | max | 254 | mm |